Production lines for production of wood pellets

Production lines for the production of wood pellets are designed to contain all the necessary technological processes to ensure the quality production of pellets from wood residues and bio products.

The main technological components are:

- reception and shredding of large wood particles

- drying and shredding of wood masses

- milling of dried particles

- storage and preparation of wood masses prior to pelletization

- pelletizing with cooling and sifting

- storage and issue of the final product

We design and build production lines for wood pellets with capacities of 2 ÷ 15 t/h. The production lines include all the components required to fulfil all the necessary technological processes, which are required to manufacture pellets of a high quality sufficient to meet with European standards.

Since the specificity of the production line (i.e. risk of fire, explosion) are so specific and challenging, the production line has embedded systems and units which fulfil the high security performance and operation, i.e. zero emission of gasses and particles and with optimized power consumption.

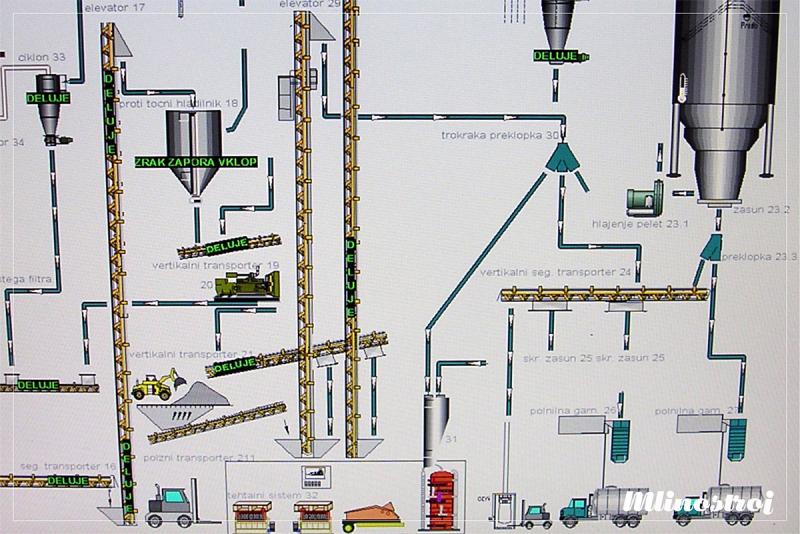

Entire production lines are automated and ensure minimal required labour. Management and control systems have modern electronic equipment, PLC and monitoring computers, which ensure reliable operation.

Slovensko

Slovensko Srpski

Srpski Hrvatski

Hrvatski Română

Română Русский

Русский Bosansko

Bosansko English

English